WIRE DRAWING LUBRICANT

Wire drawing lubricant – When wire passes through powdered lubricant in the die box, a relatively small amount of soap adheres to the surface of the wire, which is then carried into the die with the wire. The heat and the pressure of the drawing operation are considered to transform the lubricant and carrier into a plastic film that serves to reduce in large measure the friction of cold work minimize metal to metal.

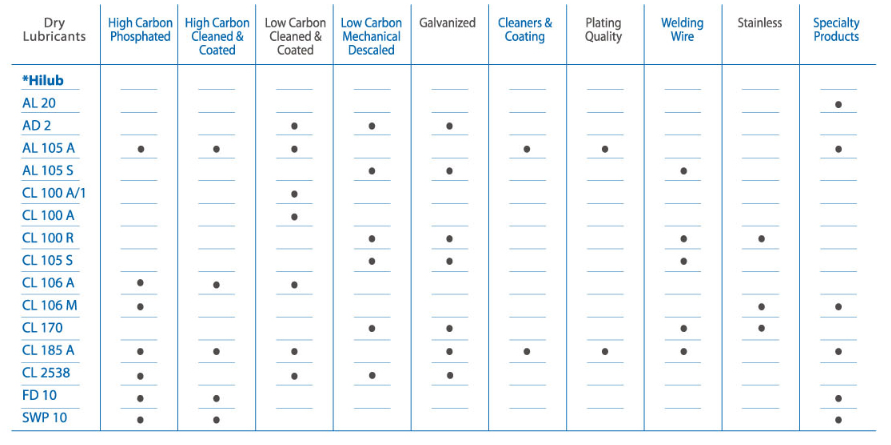

All of our dry lubricant are sold under HILUB trademark. They are metallic soaps with pronounced polarity, hence, ensuring the strongest bond to the metallic atoms.

The proper selection of lubricant for wire drawing depends on many variables including the diameter, carbon content, drawing speed, and subsequent process of the wire.

There are still over 30 lubricant available for wire drawing applications.

Many of these products are developed specifically to meet a user need with regard to a unique process. Please contact us for a better advice in your lubricant selection.

Note : There are many other lubricant types (not mentioned above) are produced by customers’ requests or specially formulated to meet certain situation and condition of the drawing machine.

Wire drawing lubricant manufactured in Indonesia